Embodied carbon is one of the key metrics used to calculate a building’s sustainability rating.

Embodied carbon is essentially a measure of the greenhouse gases associated with the products used within a building throughout their lifecycles. It includes activities such as: procuring, mining and harvesting of the raw materials; transforming these materials into construction products; transporting them to site, and incorporating them into a building. It also relates to the subsequent maintenance, replacement, removal, and disposal of the products at the end of their life.

Embodied Carbon Vs. Operational Carbon

Embodied carbon shouldn’t be confused with operational carbon; the latter refers to greenhouse gas emissions that are generated by the day-to-day running of a building, primarily the energy used for heating, ventilation and air conditioning (HVAC), lighting, building services, powering electrical goods, etc.

Both types of carbon emissions are important measures, but as the UK electricity grid transitions over to greater use of renewable energy sources and energy-efficient building design becomes more widespread, embodied carbon is becoming a more significant measure within sustainability ratings.

The UK’s Green Building Council estimates that by 2035, more than half of all built environment emissions will come from materials and construction. This means material choices made at design and procurement stages will soon play a bigger role in terms of measuring a building’s carbon performance than operational energy over its lifetime.

Higher ratings can help with planning applications, increase a building’s popularity among prospective tenants, and potentially attract higher rents, all of which explains why the use of LEC products is proving so attractive to major stakeholders, including building owners, developers, and major contractors.

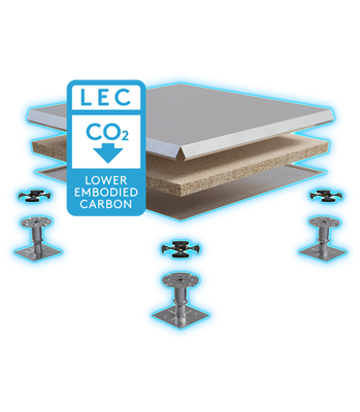

Comparing Carbon Emissions for LEC Raised Access Floors (RAF) vs Standard RAFs

But just how significant is the reduction in carbon within an LEC product vs a standard product? We can demonstrate this through a direct comparison between two of our most popular raised access floors, our market-leading RMG600 panel and our award-winning lower embodied carbon RMG600+ panel.

The RMG600+ chipboard core and steel encapsulated panel contains a minimum of 91% recycled material and across a 10,000m2 floor, delivers a reduction of 45% GWP, A1–A3 per m2 at product stage, over the RMG600 panel, not including the pedestal substructure.

Not surprisingly, there has been high demand for the RMG600+ since it was launched in 2024 and we have a growing list of prestigious projects that have already installed it.

Choosing an LEC raised access floor is a step towards securing a higher BREEAM rating and locking in lower carbon emissions. The decisions made today about substructures such as flooring will help shape the sustainability of tomorrow’s built environment.