Liquid cooling is an advanced thermal management method that uses a liquid coolant, typically water or a dielectric fluid, to absorb and transfer heat away from high-performance computing equipment. In data centres, liquid cooling offers a powerful alternative to traditional air-based systems, especially as rack densities and power demands continue to rise.

Unlike air cooling, where heat is dissipated using airflow and fans, liquid cooling places coolant closer to the heat source, making thermal transfer significantly more efficient.

How does liquid cooling differ from air cooling?

| Feature | Air Cooling | Liquid Cooling |

| Medium | Air (forced by fans) | Water or dielectric fluid |

| Thermal transfer | Less efficient | Highly efficient |

| Rack density support | 10–30 kW per rack | 30–100+ kW per rack |

| Energy consumption | Higher (requires more fan power) | Lower (less air movement required) |

| Footprint | Larger (due to space for airflow) | Compact and scalable |

| Noise and vibration | Higher | Lower |

As AI workloads, machine learning, and HPC applications increase in scale and complexity, air cooling struggles to keep up. Liquid cooling, on the other hand, efficiently manages the growing thermal load while also reducing overall energy use.

The different types of liquid cooling in data centres

There are several approaches to liquid cooling, each suited to different applications and infrastructure layouts:

- Rear door heat exchange: A passive or active liquid-cooled door is mounted on the back of a server rack. As hot air exits the servers, it's cooled by a liquid loop before re-entering the room.

- Immersion cooling: Entire servers are submerged in non-conductive dielectric fluid. Heat is absorbed directly from components and removed via a heat exchanger.

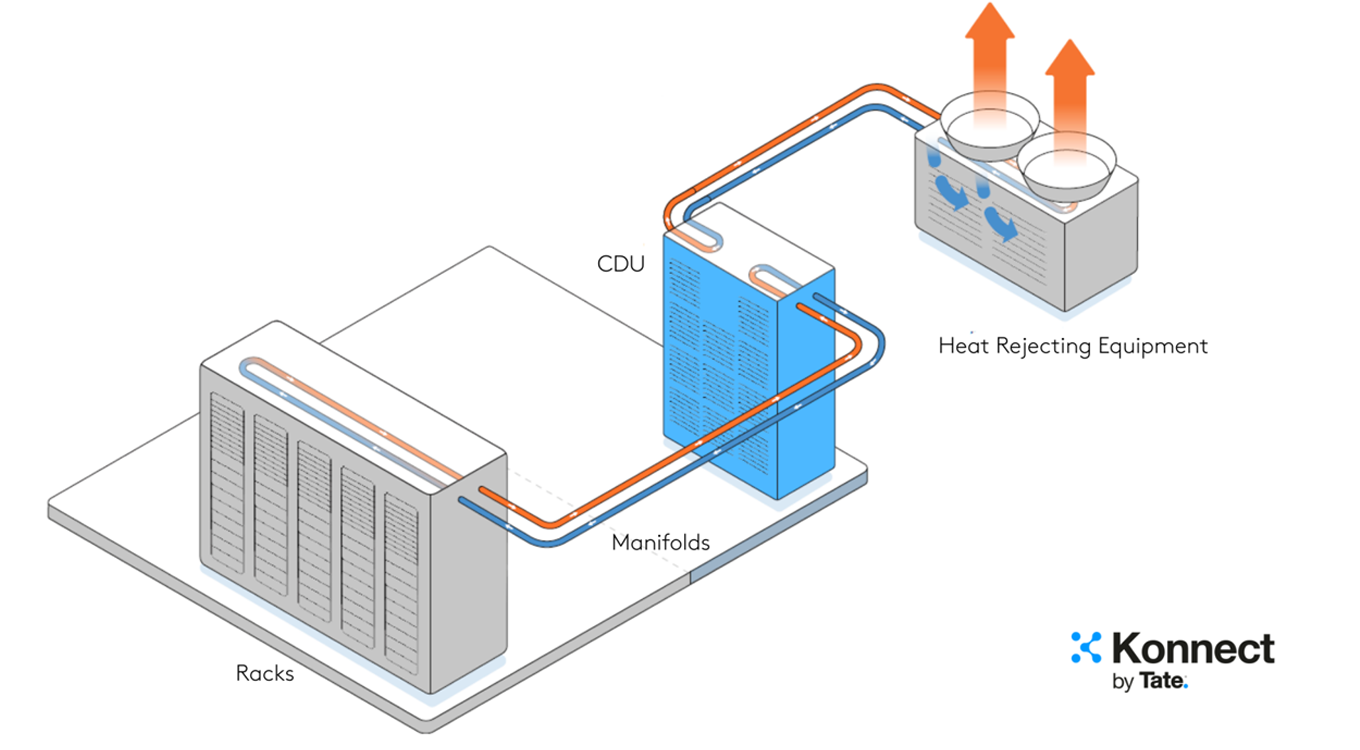

- Direct-to-chip: Coolant is delivered via cold plates mounted directly on the processors and GPUs. A liquid manifold distributes and collects coolant at the rack level.

Why the industry is moving towards direct-to-chip (D2C)

As the demand for performance grows, direct-to-chip or D2C liquid cooling is becoming the dominant approach. Here's why:

- Thermal efficiency: Delivers coolant straight to the CPU and GPU, where most heat is generated.

- Energy savings: Reduces the need for high-volume airflow and fans.

- Modularity: Scales easily with rack expansion and supports hybrid cooling designs.

- Ease of integration: With pre-integrated manifolds and hot aisle containment systems, D2C can now be deployed with minimal infrastructure disruption.

Direct-to-chip cooling provides the precision, scalability, and reliability that modern data centres require - especially in an AI-first world. As more operators look to future-proof their facilities, this technology is quickly becoming the new standard.

How to upgrade your data centre

The future of data centre cooling is liquid, and direct-to-chip systems are leading the way. Whether you're planning a new build or upgrading an existing site, now is the time to explore how liquid cooling can help you meet rising performance and sustainability demands.