Product Highlights

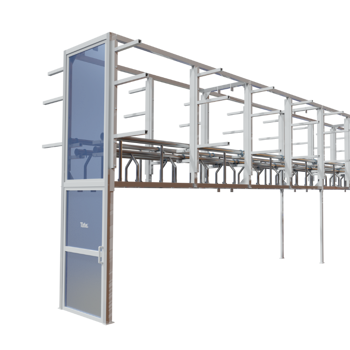

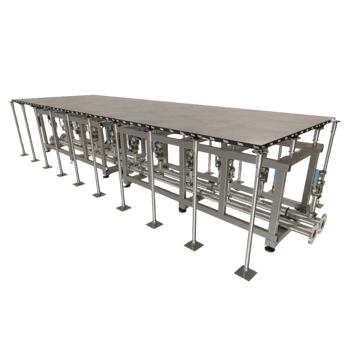

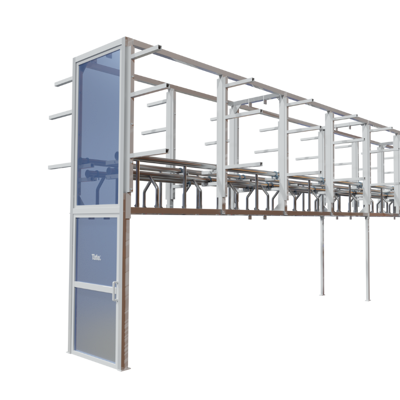

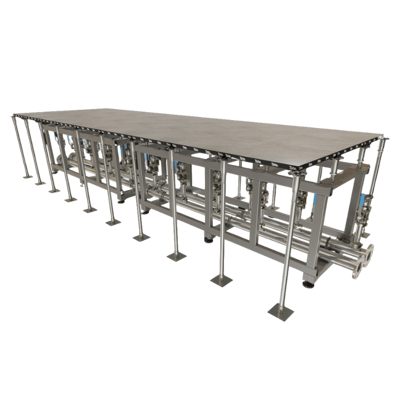

- Integrates with Tate HAC and Ceiling systems.

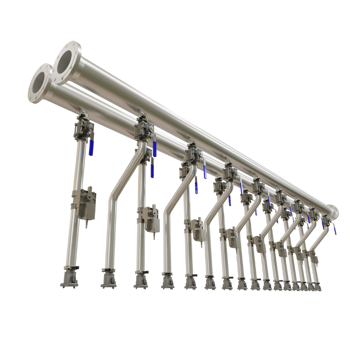

- Can be pre-integrated for simplified deployment

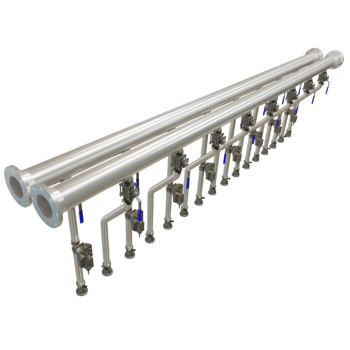

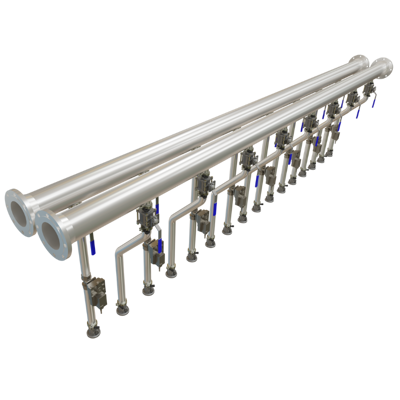

- Compatible with a wide range of cooling liquids.

- Supports extensive range of operating pressures.

- Fully traceable from supply to site

- Pressure and leak tested in a factory controlled setting prior to shipping,

Frequently Asked Questions

How do we deploy our Manifolds?

Start Your Liquid Cooling Journey with Tate

Let’s increase your cooling capacity, and set your site up for what’s next.