Structural Ceilings Built for AI Data Centres and Liquid Cooling

Overview

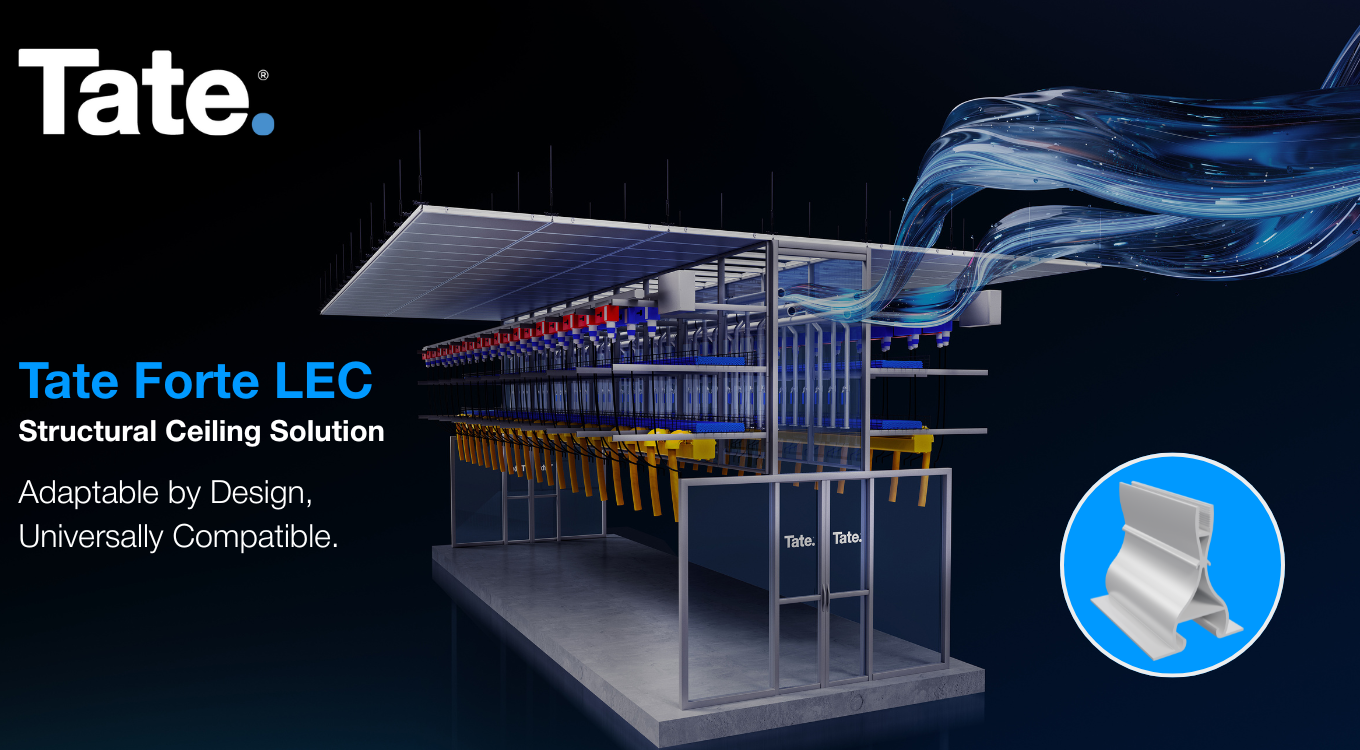

As AI workloads drive unprecedented rack densities and power requirements, data centre infrastructure must evolve. Structural ceilings are no longer passive architectural elements — they are critical load-bearing systems that support liquid cooling, high-capacity cable management, and complex overhead services. Tate Forte LEC Structural Ceiling has been engineered specifically to meet the demands of next-generation, AI-driven data centres.

Designed for both air-cooled and liquid-cooled environments, Tate Forte LEC delivers exceptional strength, flexibility, and sustainability performance, enabling data centre operators to scale with confidence.

Engineered for High-Density AI Environments

Modern AI data centres require overhead infrastructure capable of supporting heavier and more complex systems, including:

-

Liquid cooling pipework and manifolds

-

High-capacity cable containment

-

Power distribution systems

-

Mission-critical mechanical and electrical services

Tate Forte LEC provides a maximum safe point load of 4.4 kN and a maximum safe uniform load of 6.1 kN/m², making it ideally suited for high-density and hyperscale environments where structural resilience is essential.

Developed by Tate’s in-house R&D team and tested under real-world conditions, the system is designed with a safety factor of 2, ensuring long-term performance, reliability, and adaptability as workloads increase.

Optimised for Liquid Cooling Solutions

The transition to liquid cooling is accelerating as AI processing pushes thermal limits beyond the capabilities of traditional air cooling. Tate Forte LEC is purpose-built to support this shift, offering:

-

Robust overhead load capacity for liquid cooling infrastructure

-

Flexible grid configurations to accommodate evolving layouts

-

Compatibility with future cooling technologies

This flexibility allows designers and operators to integrate advanced cooling strategies without compromising safety or performance.

Lower Embodied Carbon Structural Design

According to the World Green Building Council, buildings account for approximately 39% of global energy-related carbon emissions, with materials and construction responsible for 11% of that total.

In response, the WorldGBC has set a bold vision: by 2030, all new buildings, infrastructure, and major renovations should achieve at least a 40% reduction in embodied carbon, with a strong focus on reducing upfront emissions.

As sustainability becomes an increasing priority for data centre developers worldwide, Tate Forte LEC delivers a measurable and verified solution, reinforcing Tate’s commitment to minimising climate impact across the built environment.

Key sustainability benefits include:

-

Engineered using minimal material while maintaining optimal structural load capacity

-

Manufactured with low-carbon aluminum sourced from smelters powered by renewable energy

-

59% reduction in embodied carbon across modules A1–A3 compared to the benchmark (non-LEC aluminum). *

- 54% reduction in embodied carbon across modules A - C when compared to the benchmark (non-LEC aluminum). *

Tate Forte LEC is supported by a completed, third-party verified Environmental Product Declaration (EPD), delivering transparent and comparable lifecycle data aligned with LEED v5 and embodied carbon assessment requirements.

Built for Performance. Designed for the Future.

As global standards increasingly emphasise embodied carbon reduction and performance accountability, Tate Forte LEC delivers a future-ready solution for data centres supporting AI, machine learning, and high-performance computing.

By combining advanced structural engineering with low-carbon materials, Tate Forte LEC enables developers to meet today’s demands while preparing for tomorrow’s workloads — without compromise.

*The standard benchmark represents the same ceiling grid system manufactured using 2024 world average aluminum as raw material; this comparison highlights the carbon reduction achieved by switching to LEC aluminum.