As artificial intelligence (AI), machine learning (ML), and high-performance computing (HPC) workloads continue to grow in scale and intensity, data centers around the world are facing a new thermal frontier. Increasingly, industry leaders are turning to liquid cooling – a technology once considered niche – to meet the surging demand for power, performance, and sustainability.

What Is Liquid Cooling?

Liquid cooling is a thermal management method that uses water or dielectric fluid to absorb heat directly from computing components. Unlike traditional air cooling, which relies on fans and airflow to dissipate heat, liquid systems place the coolant closer to the source—resulting in faster, more efficient thermal transfer.

| Feature | Air Cooling | Liquid Cooling |

| Medium | Air (forced by fans) | Water or dielectric fluid |

| Thermal Transfer | Less efficient | Highly efficient |

| Rack Density Support | 10-30 kW per rack | 30-100+ kW per rack |

| Energy Consumption | Higher | Lower |

| Footprint | Larger | Compact and scalable |

| Noise and Vibration | Higher | Lower |

How It Compares to Traditional Air Cooling

As server rack densities soar, liquid cooling’s ability to support loads beyond 100 kW per rack is positioning it as the solution of choice in performance-intensive environments.

Inside the Technology: Three Approaches to Liquid Cooling

Several architectures are currently in use across modern data centers:

- Rear Door Heat Exchange: These systems attach liquid-cooled doors to server racks, cooling hot exhaust air before it recirculates into the room.

- Immersion Cooling: Entire servers are submerged in dielectric fluid, allowing heat to be directly absorbed and transferred via heat exchangers.

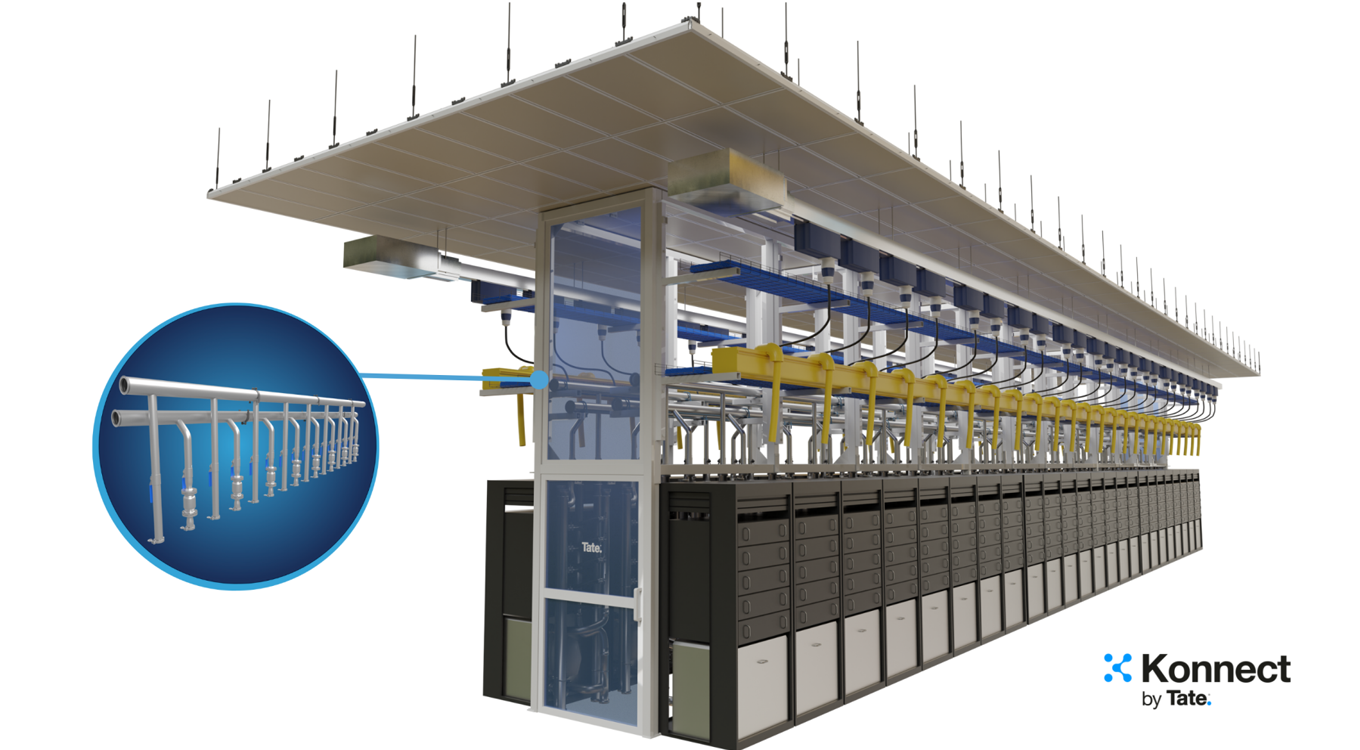

- Direct-to-Chip Cooling: This technique delivers coolant directly to the hottest components—typically CPUs and GPUs—using cold plates and a manifold system.

Direct-to-Chip Cooling Gains Momentum

Among these, direct-to-chip cooling is rapidly emerging as the industry standard. It offers a balance of precision, scalability, and energy efficiency that legacy systems can’t match.

Key benefits of direct-to-chip cooling include:

- High Thermal Efficiency: Targeted cooling of CPUs and GPUs

- Energy Reduction: Minimal reliance on fans and air handling units

- Scalable Design: Easy to expand and integrate with existing infrastructure

- Deployment Flexibility: Compatible with hot aisle containment and modular cooling systems

Planning for the Future

Industry experts agree: the shift to liquid cooling is not a matter of if, but when. Whether upgrading existing infrastructure or designing new facilities, data center operators are encouraged to explore liquid cooling technologies to stay ahead of rising compute demands and sustainability targets.

For companies seeking to adapt to the AI-driven future, now is the time to assess cooling strategies. Tate is among those leading the charge, offering direct-to-chip systems designed for rapid deployment and long-term efficiency.